A new technology is here that has the potential to reshape lithium production like fracking reshaped oil.

The global battery market is set to hit $120 billion in less than two years, and there’s a massive investor opportunity here in lithium—but this isn’t a mining play, it’s a tech play all the way.

As lithium continues to enjoy status as the hottest metal on the market, and as producers race to the finish line to bring new supply online, one little-known company just might hold technology that will give it a big edge.

In the swarm of new entrants on the lithium playing field, International Battery Metals (CSE:IBAT; OTC: RHHNF) stands out—front and center—because it’s sitting on a proprietary advanced technology that could push lithium into the production stage rapidly. It has signed an LOI with North American Lithium (NAL) to acquire all its lithium extraction process intellectual property and be restructured with NAL becoming an integral part of the company.

Where traditional solar evaporation technology takes up to 24 months to extract lithium from the brine, IBAT incoming CEO Burba says he can do it in 24 hours. That would put IBAT on the front line of new lithium coming online to meet the battery demand. And that demand is supplying our energy transition for everything from mainstreamed electric vehicles (EVs) to massive energy storage solutions and consumer electronics market that grows leaps and bounds.

The lithium game isn’t about exploration, it’s about innovation—and IBAT’s proprietary technology to be acquired from NAL was invented by the same game-changing inventor that came up with a similar tech for FMC Corp. (NYSE:FMC), one of the world’s four top lithium producers.

Lithium is currently produced through a grueling 24-month solar evaporation process that entails slowly extracting all other elements from the brine until only lithium remains.

IBAT’s technology is designed to remove evaporation ponds from the equation. As inventor-CEO John Burba puts it: “Our tech has such a high specificity for lithium that it can directly take the lithium out.”

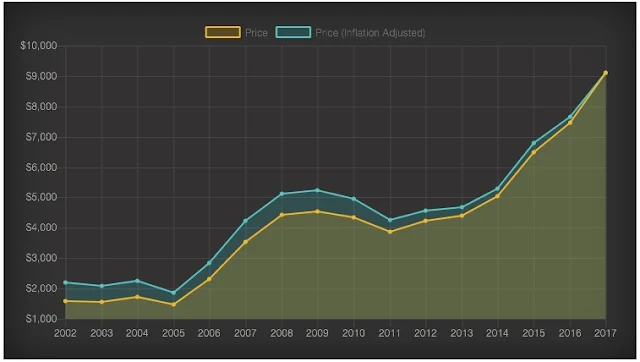

With its eye on the lithium prize, IBAT is going for fast production and commercial scalability, at a time when lithium prices per metric ton are fantastic:

Disruptive technology changes everything, and if the deal with NAL completes and IBAT’s tech breaks through successfully, it could potentially do for lithium what fracking did to unlock shale for the U.S. oil and gas industry.

Here are 5 reasons to keep a close eye on International Battery Metals (CSE:IBAT; OTC: RHHNF)

#1 Big Lithium Doesn’t Hibernate in Evaporating Ponds

The technology IBAT has an LOI to acquire, and on acquisition is considering for licensing to third party lithium producers could be a significant key to unlocking $84 billion in lithium brine resources—by making it faster and cheaper to produce.

Production capacity is now at a critical juncture. It takes a minimum of 4 years for an average Lithium brine mine to come online--and another 3-4 years to reach full capacity.

The ambitious targets for EV deployment and energy storage applications require massive Lithium mining capacity to be built much sooner than current technologies allow.

That's the chief reason why companies are aggressively pursuing new resources such as oil field brines, jadarite and hectorite clay. Lithium brine deposits are estimated to contain 66 percent of the world's 14 million metric tonnes (MT) of Lithium. That's Lithium worth $84 billion at current prices.

Unfortunately, recovery of Lithium from brine deposits is a painfully slow process. Traditional solar evaporation technology is an extremely time-intensive process, with a lengthy production cycle that can exceed 18 months.

Oilfield brines solve some of these problems due to their high Lithium concentrations. But, there's a kicker here as well-- oil field brines contain very high concentrations of dissolved ions (>100,000 mg/L), making commercial recovery of Lithium exceedingly expensive.

The technology IBAT is acquiring from NAL is based on a process that has been extracting lithium continuously in Argentina for almost 20 years.

Instead of going the traditional route of trying to isolate Lithium by removing all of those complex ions, the IBAT tech removes the Lithium directly.

According to IBAT CEO John Burba, the mastermind of this technology, the process takes the lithium out on a continuous basis. As the brine goes by, it collects lithium and lets the other impurities continue on and go straight back into the ground. The end-product is a diluted stream of lithium chloride and water that comes out as the brine goes by. That original solution has few impurities which are easily removed through an evaporation process.

The whole extraction process takes--24 hours, period—so it would mean the end of 18-24-month residencies.

If proved up for licensing, this technology could be highly disruptive, offering the fastest-to-production Lithium brine extraction solution out there. Faster means more efficient and cost effective.

While all the new entrants are struggling with costs, IBAT’s technology could put it on cost par with the Big 3 lithium producers—the lowest-cost producers right now. That includes Albemarle Corp. (NYSE:ALB), Sociedad Quimica y Minera de Chile (NYSE:SQM) and FMC.

#2 Inventor/CEO + Technical and Commercial Dream Team

Inventor John Burba—a veteran in lithium extraction—is the incoming IBAT (CSE:IBAT; OTC: RHHNF) Chairman and CEO, and he’s one of the most important pioneers in extraction technologies. He is considered a genius in this space.

IBAT’s new to-be-acquired technology is actually based on a tech that John Burba co-invented and sold in the 1990s when he was a leading technology figure at giant FMC.

Before Burba came along, everyone thought that lithium could be produced from only a limited number of brines.

That’s where Burba’s genius came into play … FMC has been using that same tech for nearly 20 years, and it’s responsible for making the purest primary lithium carbonate in the world. It’s even earned its own lithium label: “FMC-grade” carbonate.

Burba, who became the CEO of lithium extraction company Simbol Materials in 2013, has made dramatic advancements upon the old technology he co-developed for FMC.

Burba will work with Robert Miller on fund raising efforts. Miller has raised over $500 million in early-stage capital and taken 7 companies public, including NASDAQ and AMEX. He’s also founder of one of the largest gold-mining companies, Crystallex.

This inventor/CEO has already revolutionized lithium processing once. Now he’s determined to do it again, this time leading a company and a tag team that packs a professional punch.

#3 IBAT Hits the Brine, Running

Entering the lithium business just this year, IBAT (CSE:IBAT; OTC: RHHNF) has hit the ground running and they have reason to be confident in the commercial viability of their to-be-acquired advanced technology. Who wouldn’t be with the genius in this space who helped design FMC’s super-efficient lithium extraction process.

Oilfield brines are a potentially staggering resource. But it’s a resource that can be best accessed when the tech is proved up and licensed. So, again, this is like a potential shale revolution—but for lithium.

Lithium has been found extensively in North American oilfield brines, and IBAT has evaluated three so far, already securing the first. IBAT plans to set up a pilot extraction facility in early 2018, and then secure additional licenses for other high-grade lithium brines by March.

In late July, IBAT signed an option agreement to purchase 37,500 acres in the Woodbury Carper Lithium Resource Project in Illinois. This is a shallow-drilling lithium resource development opportunity in the U.S. heartland, and it’s on easy-to-permit and easy-to-drill land. It’s already got several existing wells capable of producing large volumes of lithium-rich brine, and a salt-water disposal well to get rid of brines after extraction.

Oil and gas exploration here has already discovered lithium inadvertently, so this is a great place for IBAT to launch.

By 2020, it anticipates becoming a supplier of various battery metals. And by then, well, demand will be out of this world.

#4 Strategic Positioning Across Battery Metals Space

IBAT (CSE:IBAT; OTC: RHHNF) is not setting itself up to be a one-hit metals-wonder: It’s eyeing lithium and tin and coltan.

Tin is one of the best strategic industrial metals, and as early as January 2018, IBAT plans to pay a licensing fee of $3 million to Thompson Resources to secure 3 tin properties.

Strong demand for the non-ferrous metal especially in the food and beverage packaging industries as well.

IBAT also intends to target coltan (tantalum), working with third-parties to identify and acquire high-value properties around the world.

#5 Lithium Demand is a Producer’s Dream

With global battery demand forecast to rise 7.7 percent to $120 billion already in 2019, and with the lithium market alone set to reach $1.7 billion, this is a market that won’t wait for evaporating ponds.

The global Li-ion market is expected to exceed $46 billion by 2022, growing at nearly 11 percent CAGR. What the world needs right now is plentiful supply of high-grade Lithium to power the unfolding EV revolution.

There’s more upside risk here because of battery demand than there is downside risk, according to Bloomberg New Energy Finance’s Andrew Grant.

Tesla (NASDAQ:TSLA) 70kWh Model S battery pack contains 63Kg of lithium, equivalent to the amount of lithium in 10,000 cellphones, and the EV posterchild has already accumulated more than 400K Model 3 pre-orders on its books.

Tesla, too, will use up the entire world's current supply of battery-grade lithium when it hits a production clip of 500K Model 3s in its giant Nevada Gigafactory sometime in 2018. When it opens up four more gigafactories, well …

Meanwhile, the plug-in EV market is already growing at 10x faster than its gasoline-powered counterpart. Bloomberg Finance has forecast there will be more than 100 million EVs on our roads by 2040.

The Bottom Line? This is Burba’s Brine

This is an improved technology that we’ve already seen put to work in an older, less advanced version, for giant FMC—which is today one of the world’s four major producers who have monopolized lithium.

With the same inventor behind the advanced version of this technology to take over at the helm of IBAT, confidence runs high that we’ll see a positive evaluation process for licensing.

Before the explosive entrance of the lithium-ion battery, getting lithium out of the brine wasn’t so urgent. Now, as EVs become mainstream, all the talk is of massive energy storage solutions and consumer electronics sees no end to demand in site—the brine is the new battlefield. And IBAT (CSE:IBAT; OTC: RHHNF) is poised to deliver the most decisive weapon.

Source

The global battery market is set to hit $120 billion in less than two years, and there’s a massive investor opportunity here in lithium—but this isn’t a mining play, it’s a tech play all the way.

As lithium continues to enjoy status as the hottest metal on the market, and as producers race to the finish line to bring new supply online, one little-known company just might hold technology that will give it a big edge.

In the swarm of new entrants on the lithium playing field, International Battery Metals (CSE:IBAT; OTC: RHHNF) stands out—front and center—because it’s sitting on a proprietary advanced technology that could push lithium into the production stage rapidly. It has signed an LOI with North American Lithium (NAL) to acquire all its lithium extraction process intellectual property and be restructured with NAL becoming an integral part of the company.

Where traditional solar evaporation technology takes up to 24 months to extract lithium from the brine, IBAT incoming CEO Burba says he can do it in 24 hours. That would put IBAT on the front line of new lithium coming online to meet the battery demand. And that demand is supplying our energy transition for everything from mainstreamed electric vehicles (EVs) to massive energy storage solutions and consumer electronics market that grows leaps and bounds.

The lithium game isn’t about exploration, it’s about innovation—and IBAT’s proprietary technology to be acquired from NAL was invented by the same game-changing inventor that came up with a similar tech for FMC Corp. (NYSE:FMC), one of the world’s four top lithium producers.

Lithium is currently produced through a grueling 24-month solar evaporation process that entails slowly extracting all other elements from the brine until only lithium remains.

IBAT’s technology is designed to remove evaporation ponds from the equation. As inventor-CEO John Burba puts it: “Our tech has such a high specificity for lithium that it can directly take the lithium out.”

With its eye on the lithium prize, IBAT is going for fast production and commercial scalability, at a time when lithium prices per metric ton are fantastic:

Disruptive technology changes everything, and if the deal with NAL completes and IBAT’s tech breaks through successfully, it could potentially do for lithium what fracking did to unlock shale for the U.S. oil and gas industry.

Here are 5 reasons to keep a close eye on International Battery Metals (CSE:IBAT; OTC: RHHNF)

#1 Big Lithium Doesn’t Hibernate in Evaporating Ponds

The technology IBAT has an LOI to acquire, and on acquisition is considering for licensing to third party lithium producers could be a significant key to unlocking $84 billion in lithium brine resources—by making it faster and cheaper to produce.

Production capacity is now at a critical juncture. It takes a minimum of 4 years for an average Lithium brine mine to come online--and another 3-4 years to reach full capacity.

The ambitious targets for EV deployment and energy storage applications require massive Lithium mining capacity to be built much sooner than current technologies allow.

That's the chief reason why companies are aggressively pursuing new resources such as oil field brines, jadarite and hectorite clay. Lithium brine deposits are estimated to contain 66 percent of the world's 14 million metric tonnes (MT) of Lithium. That's Lithium worth $84 billion at current prices.

Unfortunately, recovery of Lithium from brine deposits is a painfully slow process. Traditional solar evaporation technology is an extremely time-intensive process, with a lengthy production cycle that can exceed 18 months.

Oilfield brines solve some of these problems due to their high Lithium concentrations. But, there's a kicker here as well-- oil field brines contain very high concentrations of dissolved ions (>100,000 mg/L), making commercial recovery of Lithium exceedingly expensive.

The technology IBAT is acquiring from NAL is based on a process that has been extracting lithium continuously in Argentina for almost 20 years.

Instead of going the traditional route of trying to isolate Lithium by removing all of those complex ions, the IBAT tech removes the Lithium directly.

According to IBAT CEO John Burba, the mastermind of this technology, the process takes the lithium out on a continuous basis. As the brine goes by, it collects lithium and lets the other impurities continue on and go straight back into the ground. The end-product is a diluted stream of lithium chloride and water that comes out as the brine goes by. That original solution has few impurities which are easily removed through an evaporation process.

The whole extraction process takes--24 hours, period—so it would mean the end of 18-24-month residencies.

If proved up for licensing, this technology could be highly disruptive, offering the fastest-to-production Lithium brine extraction solution out there. Faster means more efficient and cost effective.

While all the new entrants are struggling with costs, IBAT’s technology could put it on cost par with the Big 3 lithium producers—the lowest-cost producers right now. That includes Albemarle Corp. (NYSE:ALB), Sociedad Quimica y Minera de Chile (NYSE:SQM) and FMC.

#2 Inventor/CEO + Technical and Commercial Dream Team

Inventor John Burba—a veteran in lithium extraction—is the incoming IBAT (CSE:IBAT; OTC: RHHNF) Chairman and CEO, and he’s one of the most important pioneers in extraction technologies. He is considered a genius in this space.

IBAT’s new to-be-acquired technology is actually based on a tech that John Burba co-invented and sold in the 1990s when he was a leading technology figure at giant FMC.

Before Burba came along, everyone thought that lithium could be produced from only a limited number of brines.

That’s where Burba’s genius came into play … FMC has been using that same tech for nearly 20 years, and it’s responsible for making the purest primary lithium carbonate in the world. It’s even earned its own lithium label: “FMC-grade” carbonate.

Burba, who became the CEO of lithium extraction company Simbol Materials in 2013, has made dramatic advancements upon the old technology he co-developed for FMC.

Burba will work with Robert Miller on fund raising efforts. Miller has raised over $500 million in early-stage capital and taken 7 companies public, including NASDAQ and AMEX. He’s also founder of one of the largest gold-mining companies, Crystallex.

This inventor/CEO has already revolutionized lithium processing once. Now he’s determined to do it again, this time leading a company and a tag team that packs a professional punch.

#3 IBAT Hits the Brine, Running

Entering the lithium business just this year, IBAT (CSE:IBAT; OTC: RHHNF) has hit the ground running and they have reason to be confident in the commercial viability of their to-be-acquired advanced technology. Who wouldn’t be with the genius in this space who helped design FMC’s super-efficient lithium extraction process.

Oilfield brines are a potentially staggering resource. But it’s a resource that can be best accessed when the tech is proved up and licensed. So, again, this is like a potential shale revolution—but for lithium.

Lithium has been found extensively in North American oilfield brines, and IBAT has evaluated three so far, already securing the first. IBAT plans to set up a pilot extraction facility in early 2018, and then secure additional licenses for other high-grade lithium brines by March.

In late July, IBAT signed an option agreement to purchase 37,500 acres in the Woodbury Carper Lithium Resource Project in Illinois. This is a shallow-drilling lithium resource development opportunity in the U.S. heartland, and it’s on easy-to-permit and easy-to-drill land. It’s already got several existing wells capable of producing large volumes of lithium-rich brine, and a salt-water disposal well to get rid of brines after extraction.

Oil and gas exploration here has already discovered lithium inadvertently, so this is a great place for IBAT to launch.

By 2020, it anticipates becoming a supplier of various battery metals. And by then, well, demand will be out of this world.

#4 Strategic Positioning Across Battery Metals Space

IBAT (CSE:IBAT; OTC: RHHNF) is not setting itself up to be a one-hit metals-wonder: It’s eyeing lithium and tin and coltan.

Tin is one of the best strategic industrial metals, and as early as January 2018, IBAT plans to pay a licensing fee of $3 million to Thompson Resources to secure 3 tin properties.

Strong demand for the non-ferrous metal especially in the food and beverage packaging industries as well.

IBAT also intends to target coltan (tantalum), working with third-parties to identify and acquire high-value properties around the world.

#5 Lithium Demand is a Producer’s Dream

With global battery demand forecast to rise 7.7 percent to $120 billion already in 2019, and with the lithium market alone set to reach $1.7 billion, this is a market that won’t wait for evaporating ponds.

The global Li-ion market is expected to exceed $46 billion by 2022, growing at nearly 11 percent CAGR. What the world needs right now is plentiful supply of high-grade Lithium to power the unfolding EV revolution.

There’s more upside risk here because of battery demand than there is downside risk, according to Bloomberg New Energy Finance’s Andrew Grant.

Lithium prices have made prodigious runs to all-time highs.

Tesla (NASDAQ:TSLA) 70kWh Model S battery pack contains 63Kg of lithium, equivalent to the amount of lithium in 10,000 cellphones, and the EV posterchild has already accumulated more than 400K Model 3 pre-orders on its books.

Tesla, too, will use up the entire world's current supply of battery-grade lithium when it hits a production clip of 500K Model 3s in its giant Nevada Gigafactory sometime in 2018. When it opens up four more gigafactories, well …

Meanwhile, the plug-in EV market is already growing at 10x faster than its gasoline-powered counterpart. Bloomberg Finance has forecast there will be more than 100 million EVs on our roads by 2040.

The Bottom Line? This is Burba’s Brine

This is an improved technology that we’ve already seen put to work in an older, less advanced version, for giant FMC—which is today one of the world’s four major producers who have monopolized lithium.

With the same inventor behind the advanced version of this technology to take over at the helm of IBAT, confidence runs high that we’ll see a positive evaluation process for licensing.

Before the explosive entrance of the lithium-ion battery, getting lithium out of the brine wasn’t so urgent. Now, as EVs become mainstream, all the talk is of massive energy storage solutions and consumer electronics sees no end to demand in site—the brine is the new battlefield. And IBAT (CSE:IBAT; OTC: RHHNF) is poised to deliver the most decisive weapon.

Source